We design and build industrial systems for the food, beverage, spirits, and process industries — from small-scale producers to mid-size and large manufacturers.

Our systems recover waste heat, automate production, and reduce manual work, improving reliability, lowering costs, and supporting sustainable operations.

Based in Europe, delivering systems worldwide.

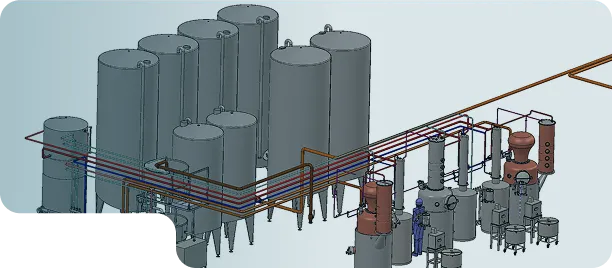

Kothe distillation equipment

Next-generation multi-stage heat-pump technology that generates 110 °C super-pressurised water or low-pressure steam efficiently.

PLC-based, recipe-driven automation for consistent distillation quality — cutting energy and cooling water use, lowering operator workload, and ensuring repeatable results.

From artisanal producers to large-scale operations, our integrated systems unite Kothe’s distillation craftsmanship with Lovassy’s engineered technologies — delivering lasting performance, automation, and sustainability.

Kothe Small Stills (<2000L)

For artisanal and small-batch producers.

For distilleries enhancing performance.

Kothe Big Stills (>2000L)

Our flagship complete future-ready solution.

We envision a food and beverage industry built on complete ecological cycles — where every process conserves energy, reuses water, and turns by-products into value.

Our mission is to unite environmental and business sustainability. We design technologies that waste no water or energy and help our partners operate efficiently, responsibly, and profitably.

Lovassy & Co. was founded by Lovassy György, M.Sc. Food Engineering, whose 30 years of experience in fruit processing, distillation technologies, and automated plant design shaped our engineering foundations. His focus on tailored, high-quality systems and personal support earned regional recognition and lasting client trust.

We remain true to those principles — practical, approachable, and committed to building technologies that endure. With the next generation now involved, our work continues with a clear purpose: designing sustainable systems that serve both industry and future generations.

Our in-house developments — including the HICOVERY waste-heat recovery system — reflect our dual commitment to efficiency and sustainability. We continue to refine processes that reduce waste, close resource cycles, and strengthen our partners’ long-term competitiveness.

Learn how we empower SMEs for a sustainable future

Whether you’re refining existing plans or building a new plant from the ground up, we provide comprehensive support at every stage.

Personal consultations — including on-site assessments — to define objectives, specifications, and timelines.

Systems engineered to your process parameters for maximum efficiency and long-term reliability.

Precise installation and system integration to ensure a seamless start-up.

Comprehensive testing, calibration, operator training, and technical support to keep your plant performing at its best.

We build PLC-based control systems and robotic packaging solutions that make production simpler, steadier, and more precise — giving teams reliable control with less manual work.

Our systems are designed to use less energy and water — recovering waste heat, reusing cooling water, and cutting running costs while reducing environmental impact.

We engineer with the whole business in mind — understanding how each plant fits into daily operations to deliver technology that runs efficiently and pays off long-term.

An incomplete selection of successful client relationships we’ve built over the past 15 years.

We’d be glad to hear from you. You’re welcome to share questions, concepts, or early-stage ideas.

Our first conversations are exploratory and technical in nature — with no commitment expected on your side.

Please contact the right person directly:

Opening Hours: M-F 9:00-17:00 CET